The 505DR® dual-redundant steam turbine control is a state-of-the-art digital control platform designed to reliably control and protect single valve and single-extraction steam turbines with the advantage of dual-redundancy for maximum turbine reliability and availability. Redundancy is managed at the operating system level using Woodward’s RTN (Real Time Network), allowing ultra-fast changeovers and “bumpless” transitions.

Applications:

Steam Turbine Control

- Single Valve

- Single-Extraction/Admission

Driving generators, compressors, turbo-expanders, fans, and pumps.

The 505DR is a highly efficient redundant turbine control. It includes the turbine control, system sequencer, operator control panel and first out indicator. This design minimizes external devices and wiring and eases troubleshooting.

The 505DR® system assigns one control as System Controller (Syscon) which actively controls the turbine. The second unit is configured as Backup. The system automatically assess the heath of the Syscon and will initiate a fast switchover when a failure occurs. Switchover can also be initiated manually. The system tightly synchronizes software states and memory from the Syscon to the Backup, insuring that control outputs remains steady with no effect on turbine operation (a true “bumpless” transition).

Features:

Integrated Graphical Front Panel HMI Screen

- Multilingual screens including Chinese for easier operator use, diagnosis and control

- Large screen allows easy navigation and icon view of parameters and performance

- Real time trending locally viewable by operators and engineers

- Graphic steam map with current operating point view for extraction and admission

- Configurable tag names to easily identify connections

- Internal “Turbine Simulator” for off-line training and advance testing before system changes

Improved Communications

- Ethernet communications for connectivity to plant DCS, service tools and RemoteView operator control panels

- Distributed I/O (LinkNet-HT) enables expanded control of additional turbine package equipment startup and control

- CANOpen actuator connectivity for Woodward VariStroke actuators and DSLC-II power management networks

Intelligent / Adaptive Control Algorithms

- Next generation advance load rejection performance

- 3 critical speed avoidance bands

- Reverse rotation sensing and alarm

- OptiTune adaptive PID technology for optimum set-up of turbine performance

- Acceleration PID that limits overshoots for a stable and efficient plant startup

- High speed data logs monitoring turbine operation and stress including run time and first out trip information

- Vibration monitoring for protection and control (Sensor kit 8928-7482)

Improved Service/User Tools

- Cyber compliant password enabled logins

- RemoteView (8928-5311) program enables virtual monitor and control from a remote workstation or mobile device

- Control Assistant service tool enabled to easily configure, save, compare and view settings and data logs

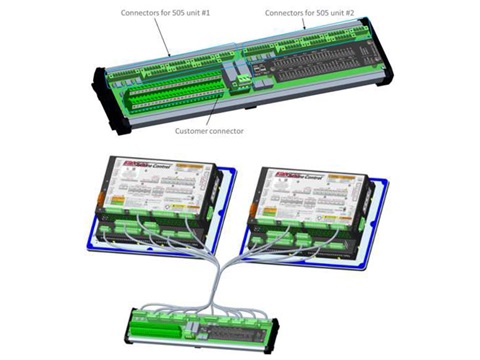

Woodward also offers an optional FTM (Field Termination Module) to allow easy multiplexing of redundant signals and facilitates quick installation and commissioning. (5541-705)

Application Notes

Brochure

Product Specification

Software Manual

Technical Manual

Software