Search our Aerospace and Industrial products below or look up software, manuals, and technical documentation in the Global Search.

Vertex Compressor Control

Tired of trying to navigate and diagnose compressor performance and surge events with your current “black box” control? Want to …

LEARN MORE

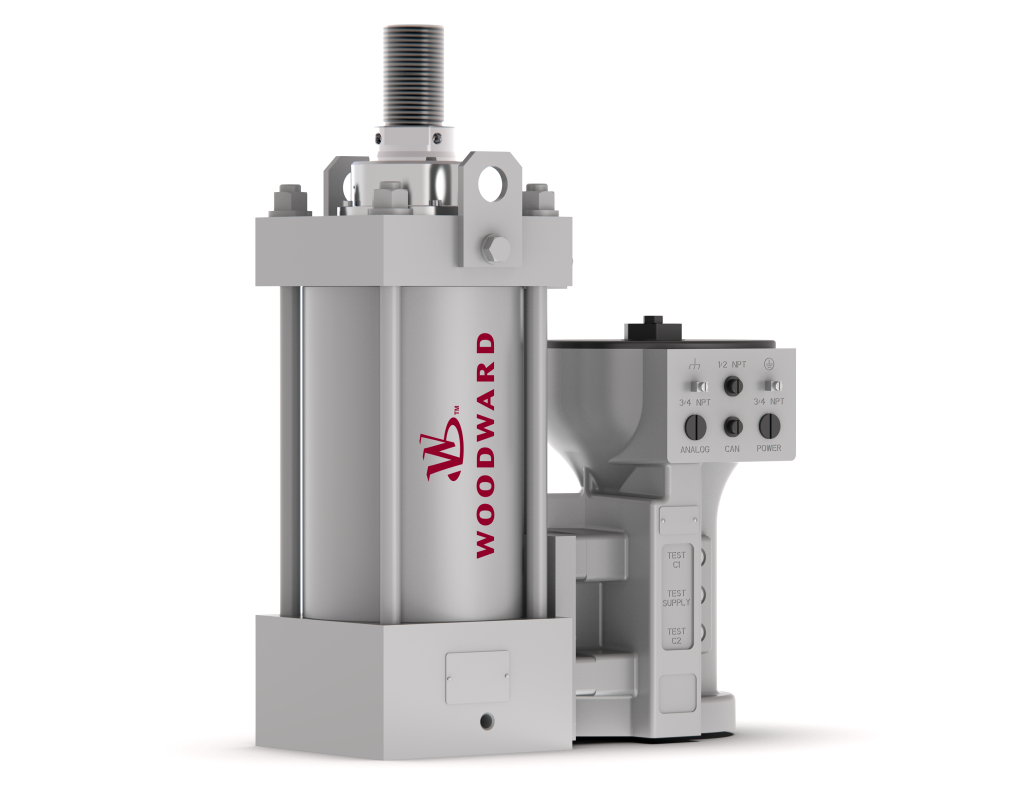

VariStroke Linear Electro-Hydraulic Valve Actuator

VariStroke is Woodward’s line of linear electro-hydraulic valve actuators for operation of steam or hydro turbine control valves. These linear …

LEARN MORE

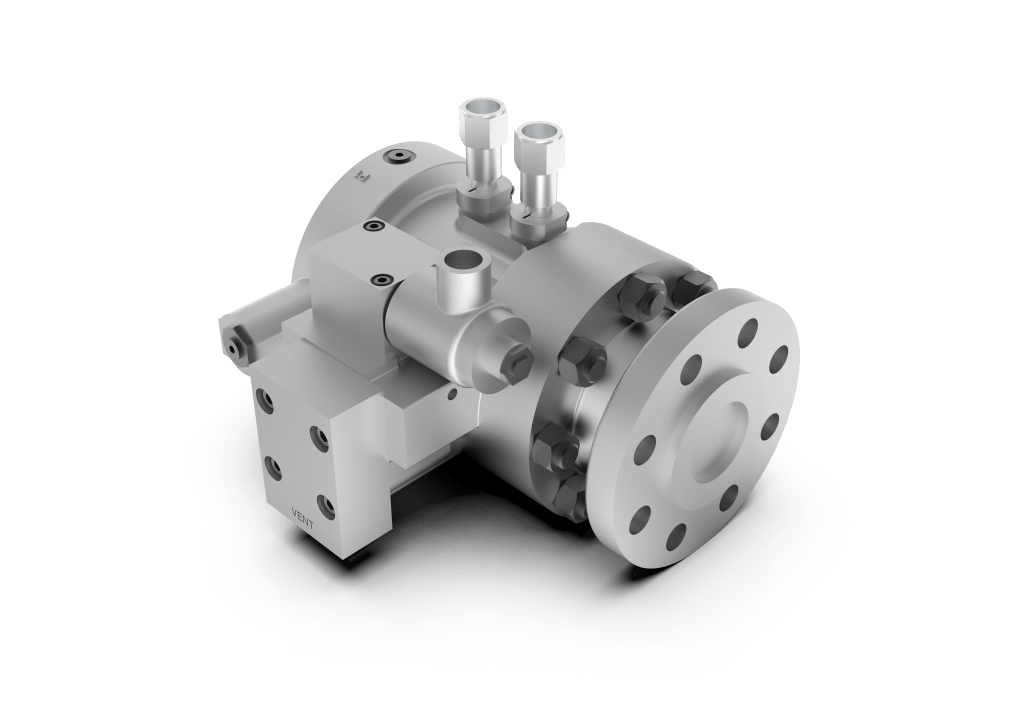

QuickTrip

Electro-Hydraulic Trip Block Assembly for Industrial Steam Turbines

The QuickTrip trip block assembly is designed for use in steam, gas, and …

GS0V50 Fuel Isolation Valve

The Woodward GSO50 fuel isolation valve is designed to provide extremely fast shutoff of gaseous fuel flow to an industrial …

LEARN MORE

GS16 Gas Fuel Metering Valve

The GS16/GS16DR gas fuel metering valve is an electrically actuated fuel valve with an on-board, electronic positioner controller.

Product Specification: …

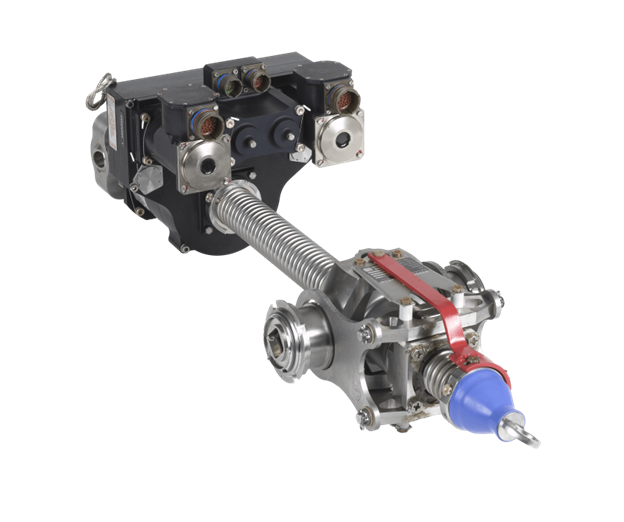

Horizontal Stabilizer Trim Actuator (HSTA)

As a leader in horizontal stabilizer trim actuation, Woodward equips many civil and military programs. Our HSTA systems enable to …

LEARN MORE