HEAVY DUTY GAS TURBINE

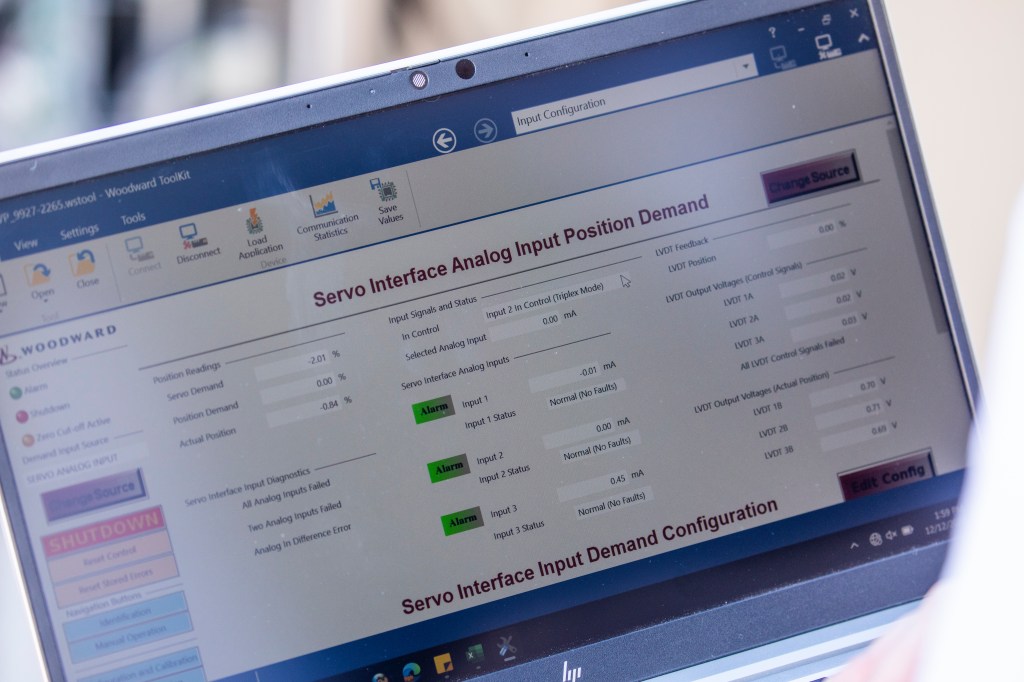

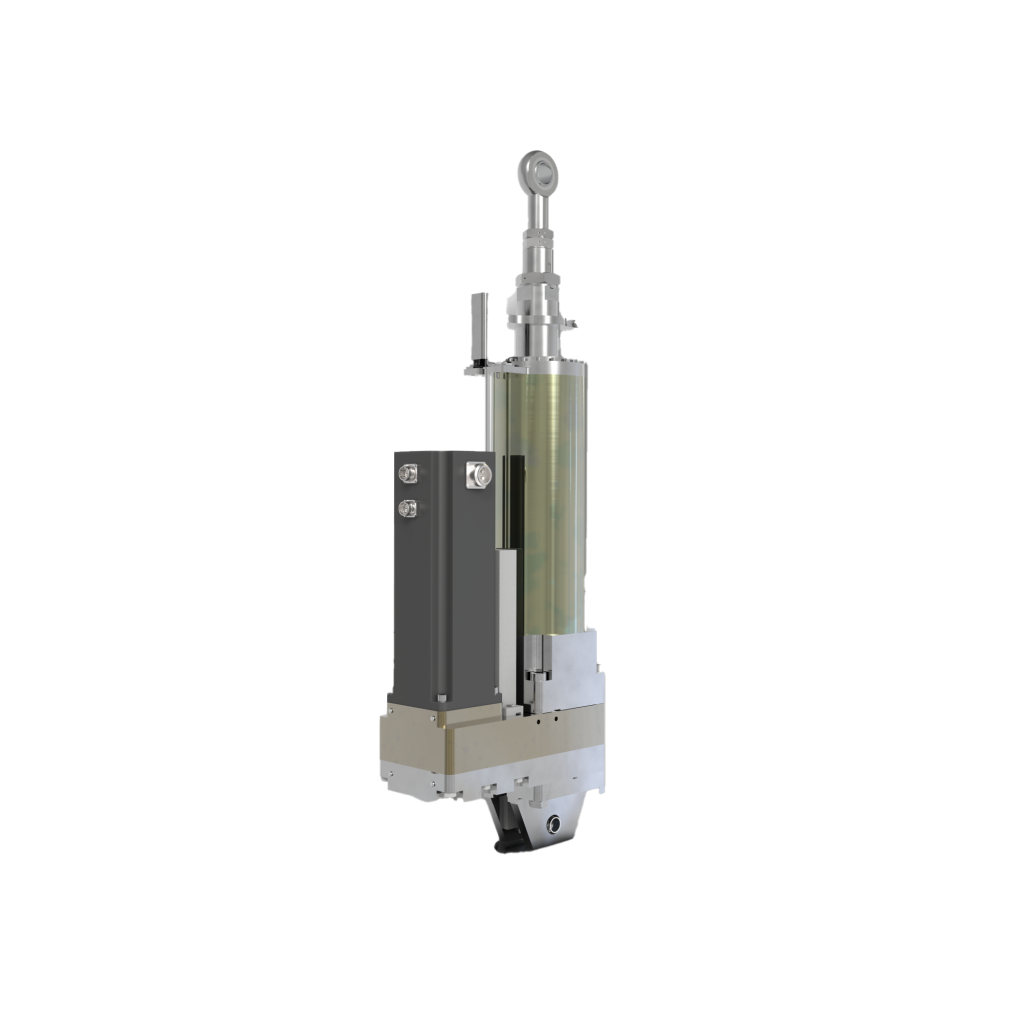

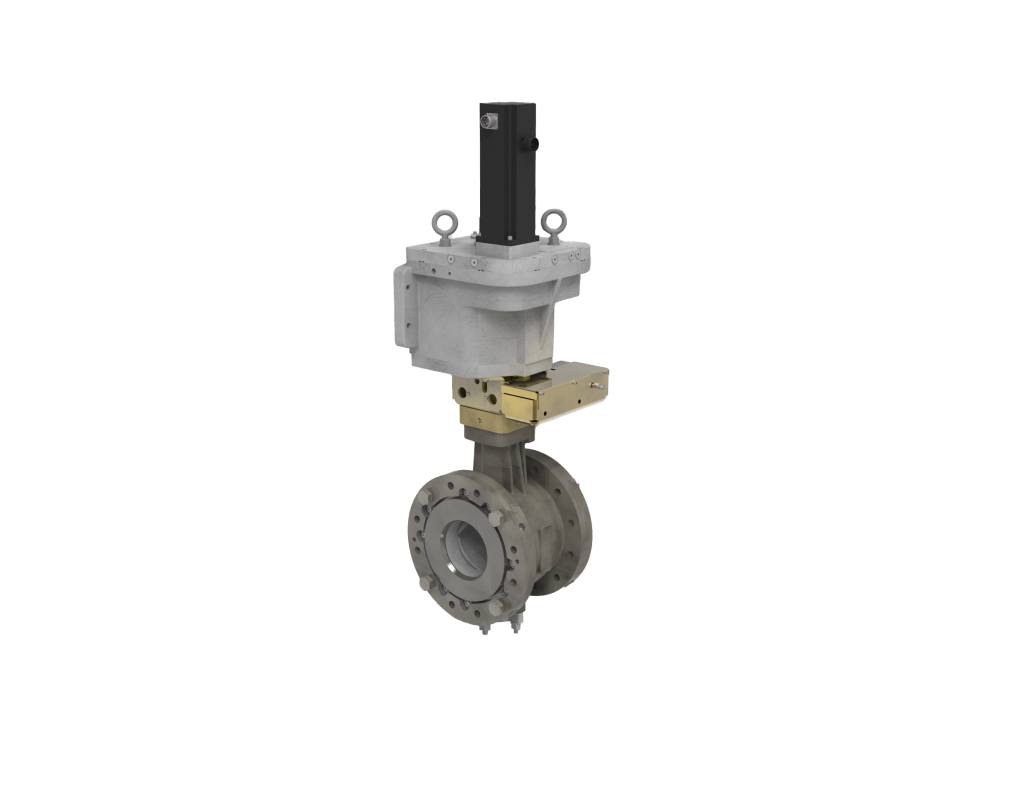

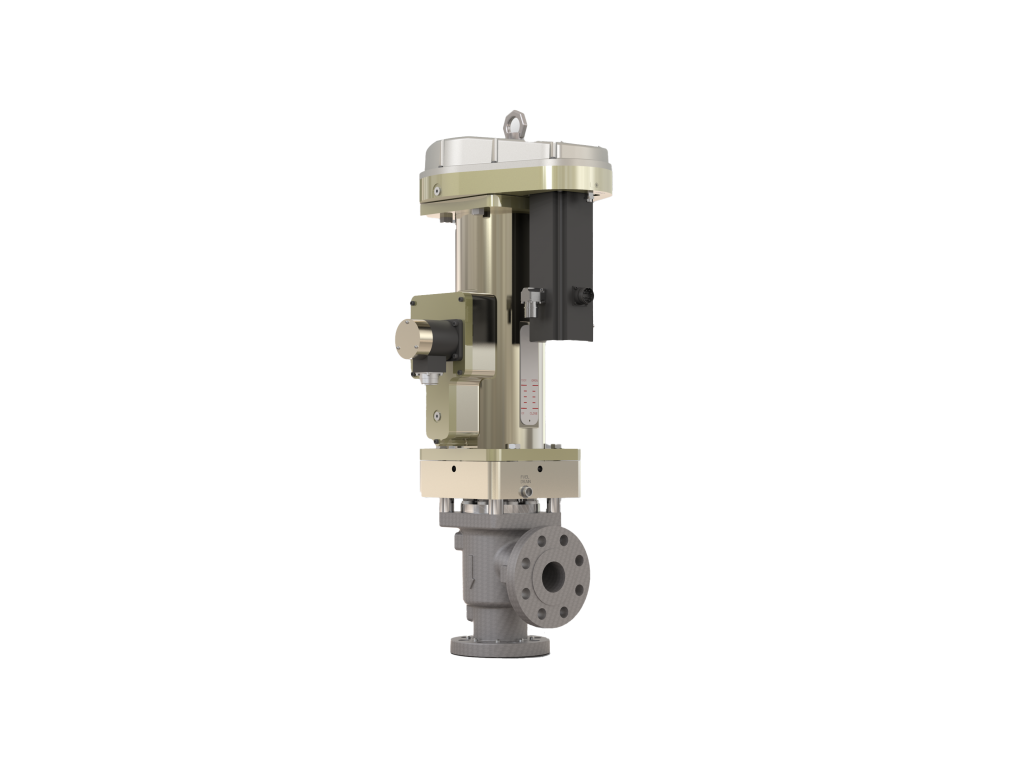

Electric Fuel Valves

Electric Fuel Valves

and Actuators

Heavy Duty Gas Turbines have increasingly been dispatched to support the grid during the renewable energy transition. These market conditions drive fleet owners to operate their assets as peakers, creating the need for frequent starts. Start-up reliability has become a key success factor for these units. Hydraulic gas fuel control valves and actuators have gotten the job done for decades, but not without known risks and issues that can result in failed startups and unplanned turbine downtime.

See why Platte River Power Authority made the switch to electric valves in the video.

Want to learn more about how going electric can help your plant?

contact us