Features & Functionality

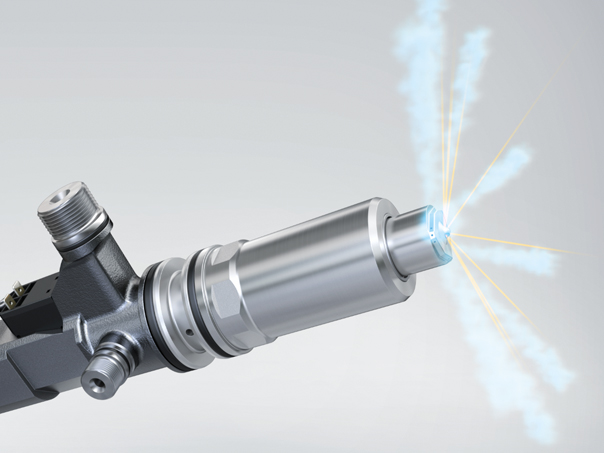

The Medium Pressure Injection (MPI) product line features a direct actuated technology for port fuel injection or medium pressure direct injection. The family supports different fuels and combustion strategies and offers liquid fuels (methanol, ethanol or ammonia) and gaseous fuels (hydrogen) injection with electronically controlled Common Rail technology, up to 250 bar injection pressure. The injectors can be customized to match every engine’s requirement in terms of nozzle positioning, fuel inlet, and packaging while maintaining high commonality with the family.

The High-Pressure Dual Fuel (HPDF) product line features a twin nozzle concept, with two injectors in one unit: one side for ammonia or methanol injection up to 700 bar injection pressure with electronically controlled Common Rail technology, the other side for diesel injection for pilot-ignition or full back-up capability. The diesel-side is offered with mechanical injection (pump-line-nozzle technology, PLN) or state of the art Common Rail Technology, customized to engine requirements. The twin-needle dual fuel injector concept is much easier to integrate into a cylinder head compared to two separate injectors with the advantage of both nozzles being in the center of the cylinder for optimized combustion. The modular approach enables adaptation of the design to match individual customer requirements. Woodward is committed to supporting the global transition to low carbon fuels and helping its customers meet the performance demands of new engines. The company has been working closely with engine OEMs to develop and validate the new product lines.

Key Product Variants Include

- Medium Pressure Injection (MPI) product line

- High-Pressure Dual Fuel (HPDF)

Key Features

- Combustion engines with the ability to be operated with P2X fuels will offer the most attractive pathway for decarbonization in many marine applications.

- Outstanding flexibility and versatility ensure future-proof investment.

- HPDF solutions from Woodward L’Orange can even effectively deal with fuel switches during the engine’s lifetime.

- Common-rail diesel side with 100% diesel capability and pressures of up to 2,200 bar ensure 100% backup power with outstanding performance and a fully optimized combustion process.

- High gas pressures of up to 500 bar enable a defined mass flow throughout the injection and fully optimized gas combustion.

- Compact, space-saving injector design suits the vast majority of engine configurations.

- High-level fuel flexibility ensures easy adaptation to future-proof your investment.

- Leading engine manufacturers (OEM) trust in our products.